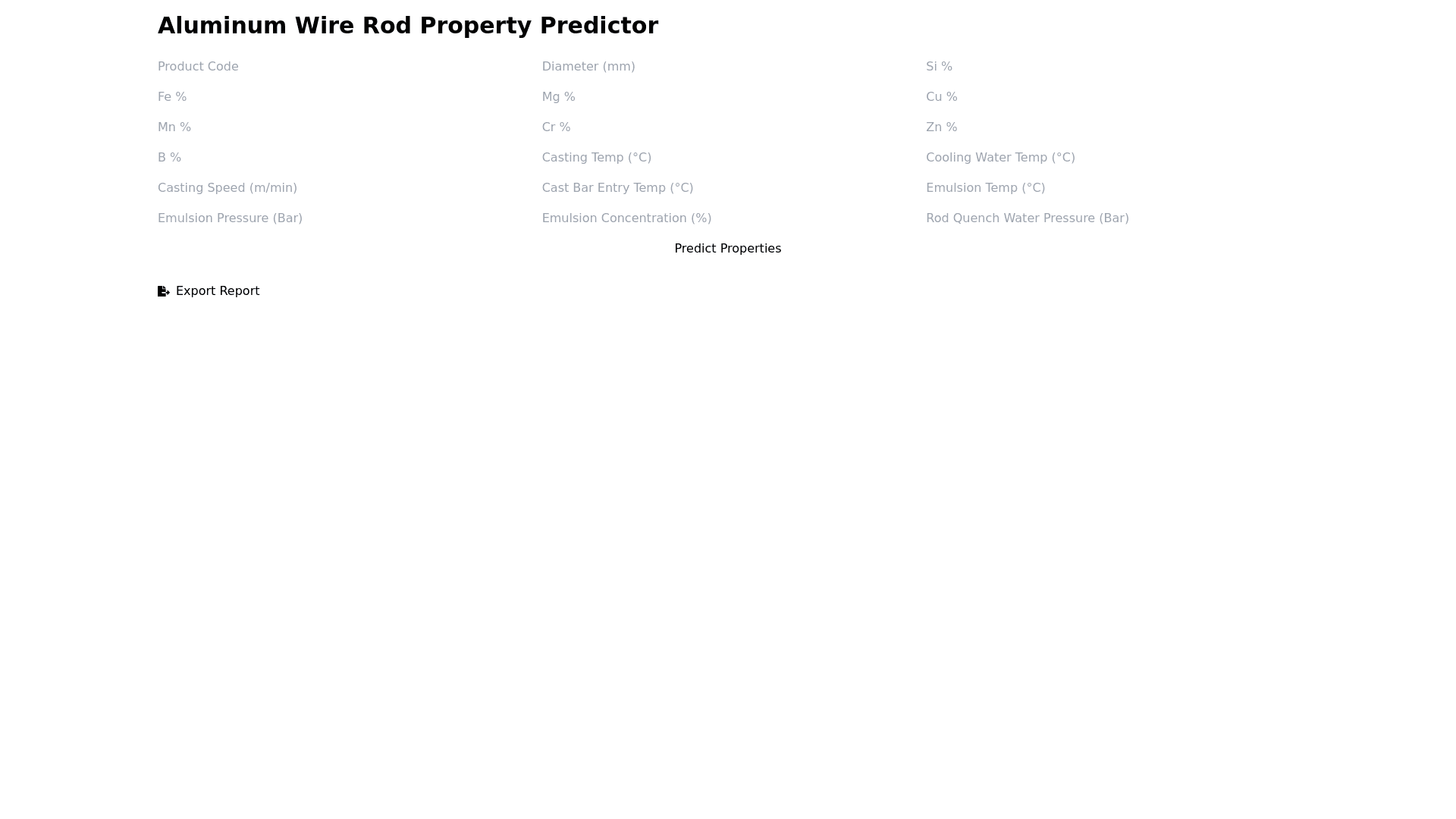

Aluminum Wire Rod Prediction - Copy this React, Tailwind Component to your project

Design an advanced AI/ML powered web based platform using React, TailwindCSS, and TensorFlow.js to predict the physical properties of aluminum wire rods. The system should incorporate the following features: 1. **Input Data**: Allow users to input and adjust the following parameters dynamically: `Product_Code` `Diameter_mm` `Chemical_Composition`: ['Si_%', 'Fe_%', 'Mg_%', 'Cu_%', 'Mn_%', 'Cr_%', 'Zn_%', 'B_%'] `Casting_Temp_C`, `Cooling_Water_Temp_C`, `Casting_Speed_m/min`, `Cast_Bar_Entry_Temp_C` `Emulsion_Temp_C`, `Emulsion_Pressure_Bar`, `Emulsion_Concentration_%` `Rod_Quench_Water_Pressure_Bar` 2. **Prediction Output**: Implement a machine learning model (TensorFlow.js or Python backend) to predict: `UTS_kg/mm2` `Elongation_%` `Conductivity_%IACS` Display predictions based on real time inputs. 3. **Product Specifications Integration**: Based on the input diameter and product code, automatically fetch predefined product specification ranges for comparison: **Electrical Conductivity**: ≥ 61.50% (for WE10, WE12, WF10, WF12) Other codes (WE20, WF20, WC10, WC12) with specific conductivity ranges. 4. **Dynamic Visualization**: Create real time, dynamic charts (e.g., using D3.js or Chart.js) to display how changes in chemical composition and casting parameters affect the predicted UTS, Elongation, and Conductivity. Visual comparisons with standard product ranges (NALCO standards) based on the input `Product_Code` and diameter. 5. **AI Driven Optimization**: Use AI techniques to suggest parameter adjustments for improving the quality (UTS, Elongation, Conductivity) of wire rods. Highlight deviations and suggest optimal parameter ranges to keep the product within desired specifications. 6. **Responsive UI**: Build a user friendly, responsive UI for seamless usage across desktop and mobile. Implement multilingual support for different languages like English and Hindi, along with accessibility features. 7. **Real Time Alerts**: Add real time monitoring and alerting system to notify users if any input parameter crosses an optimal threshold (e.g., casting temperature, cooling water temperature, or emulsion pressure). 8. **IoT Integration**: Stream real time data from IoT sensors on production machines into the system to provide live updates on production conditions (casting temp, pressure, etc.). 9. **Export and Reporting**: Allow users to generate comprehensive reports (PDF/CSV) summarizing the input parameters, predicted properties, and any adjustments suggested by the AI. 10. **Performance Optimization**: Ensure smooth rendering and performance with conditional rendering techniques, rendering only the required components and data views when tabs or input values change.